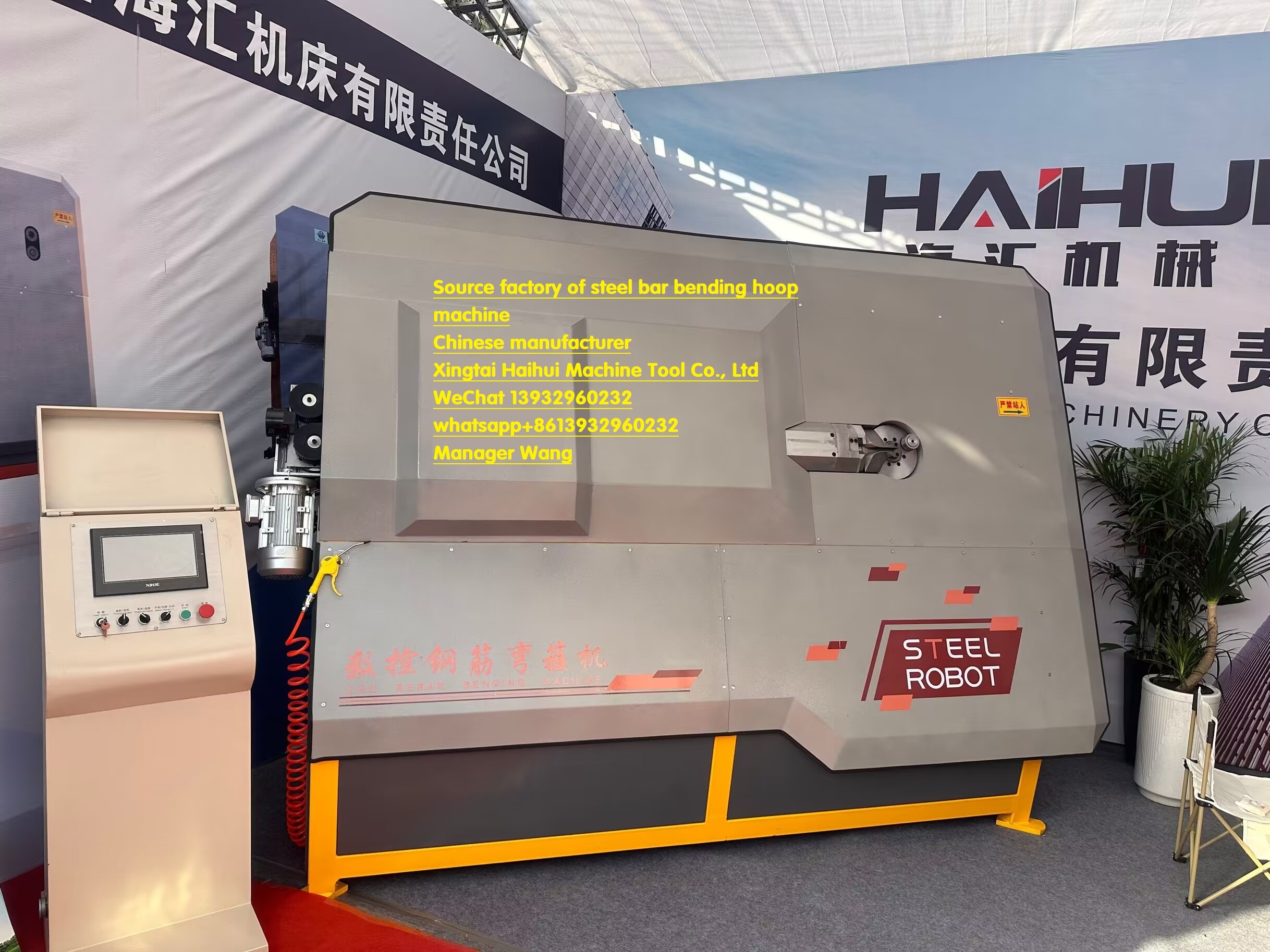

In the fast-paced world of construction and manufacturing, the quest for enhanced efficiency is constant. Among the various tools and technologies available, the Fully automatic CNC hoop reinforcement machine stands out as the ultimate solution.

This state-of-the-art machine is engineered to optimize every aspect of hoop reinforcement production. Its fully automated processes eliminate the need for time-consuming manual operations, reducing the risk of errors and increasing productivity.

The speed and accuracy with which it works are unparalleled. It can rapidly churn out precise hoop reinforcements, ensuring a seamless supply for construction projects.

The machine’s intelligent control systems allow for easy customization and programming, enabling it to adapt to different project requirements with ease. This flexibility ensures that it can handle a wide range of tasks, making it a versatile asset in any production setup.

Not only does it improve the efficiency of the production process, but it also reduces material waste and lowers labor costs. Its reliability and durability mean that it can operate consistently without frequent breakdowns, minimizing disruptions to the workflow.

결론적으로, when it comes to improving efficiency in the production of hoop reinforcements, the Fully automatic CNC hoop reinforcement machine is undoubtedly the best choice. It empowers businesses to meet deadlines, deliver high-quality products, and stay ahead in a competitive market.