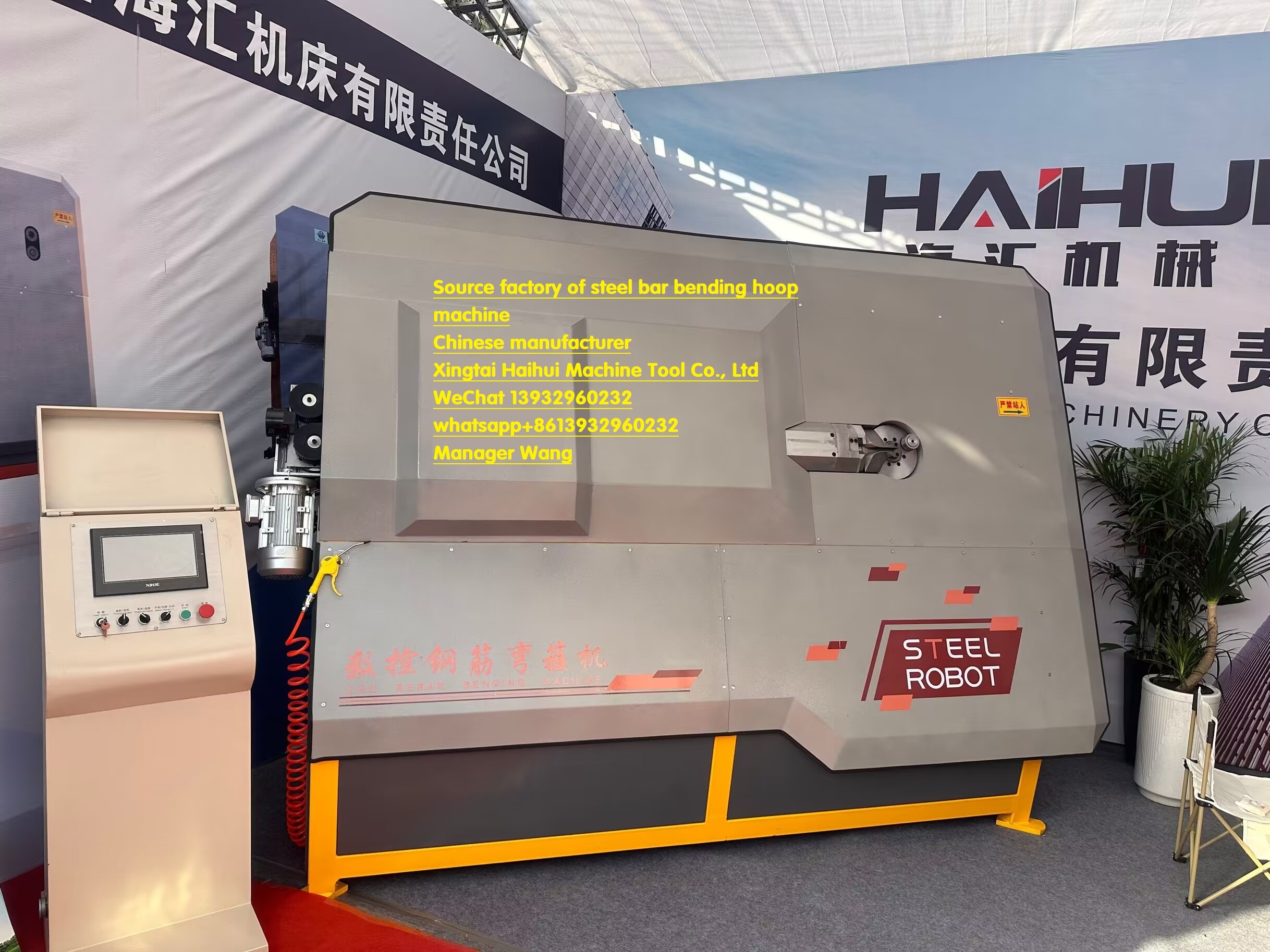

In the ever-evolving landscape of construction and manufacturing, the Fully automatic CNC hoop reinforcement machine emerges as a game-changer, leading the way in innovative hoop reinforcement processing.

This cutting-edge machine is engineered with precision and intelligence at its core. It combines advanced technology with seamless automation to redefine the way hoop reinforcements are produced.

The fully automatic feature of the CNC hoop reinforcement machine eliminates the need for manual intervention, ensuring consistent and accurate results every time. Its ability to precisely shape and size the hoop reinforcements to exact specifications is a testament to its technological prowess.

The speed and efficiency it offers are unparalleled. It can process a large volume of hoop reinforcements in a fraction of the time it would take using traditional methods, significantly boosting productivity and meeting the demands of high-paced construction projects.

Moreover, its flexibility and adaptability allow it to handle a wide range of materials and designs, making it suitable for various applications and project requirements.

The machine’s user-friendly interface and intuitive controls make it easy to operate and program, reducing the learning curve for operators and maximizing its usability.

In addition, its advanced safety features ensure a secure working environment, protecting both the operators and the equipment.

The Fully automatic CNC hoop reinforcement machine is not just a piece of equipment; it’s an innovation that is shaping the future of the construction and manufacturing industries. It’s setting new standards for quality, efficiency, and precision in hoop reinforcement processing.

결론적으로, as an innovative leader, this machine is driving progress and enabling businesses to stay ahead in a competitive market by delivering superior products with enhanced productivity and reduced costs.