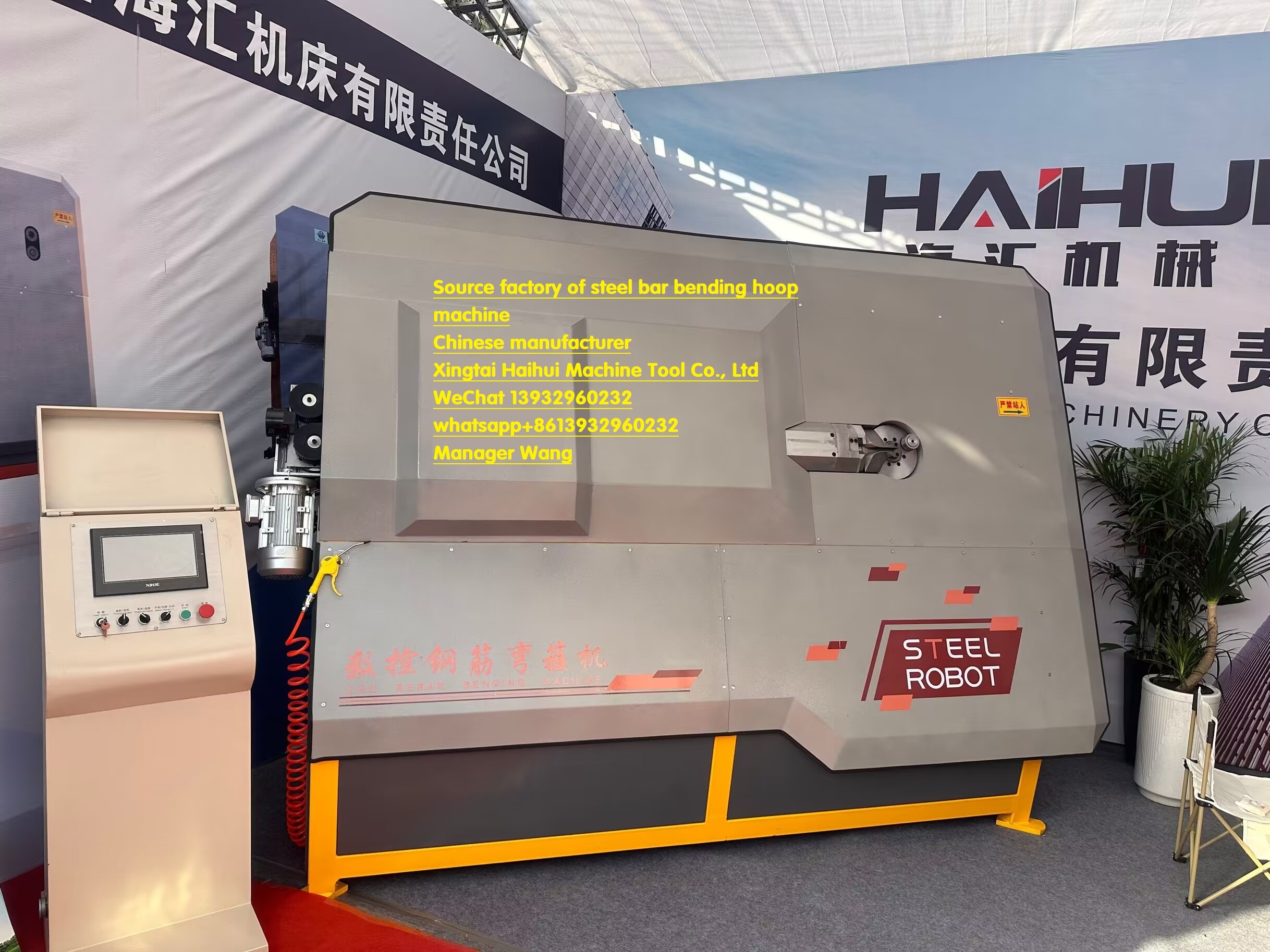

Dans le secteur de la construction dynamique et exigeant, the Fully automatic CNC hoop reinforcement machine has emerged as a indispensable and powerful ally.

This advanced piece of equipment brings a host of benefits that significantly enhance the efficiency and quality of construction projects. Its fully automatic operation means that the process of manufacturing hoop reinforcements is streamlined and highly precise.

The machine’s ability to produce consistent and accurately sized hoop reinforcements is crucial in ensuring the structural integrity of buildings. It eliminates human errors and variations, providing a reliable solution for reinforcing concrete structures.

The speed at which it works is a major advantage, permettant aux équipes de construction de respecter des délais serrés et de maintenir les projets dans les délais. De plus, it can handle large volumes of production, meeting the demands of even the most extensive construction endeavors.

The flexibility of the Fully automatic CNC hoop reinforcement machine is another notable feature. It can be programmed to create hoop reinforcements of various shapes and sizes, adapting to the specific requirements of different architectural designs.

This not only saves time but also reduces material waste, contributing to cost savings and environmental sustainability in the construction process.

En conclusion, as a powerful assistant, the Fully automatic CNC hoop reinforcement machine plays a vital role in modern construction, enabling the industry to build stronger, faster, and more efficiently.