In the realm of bending technology, a revolutionary force has emerged – the CNC automatic bending machine. This game-changing innovation is rewriting the rules and transforming the landscape of how materials are bent and shaped.

The traditional methods of bending often involved manual labor, guesswork, and inherent limitations in accuracy and repeatability. However, the advent of the CNC automatic bending machine has shattered these constraints.

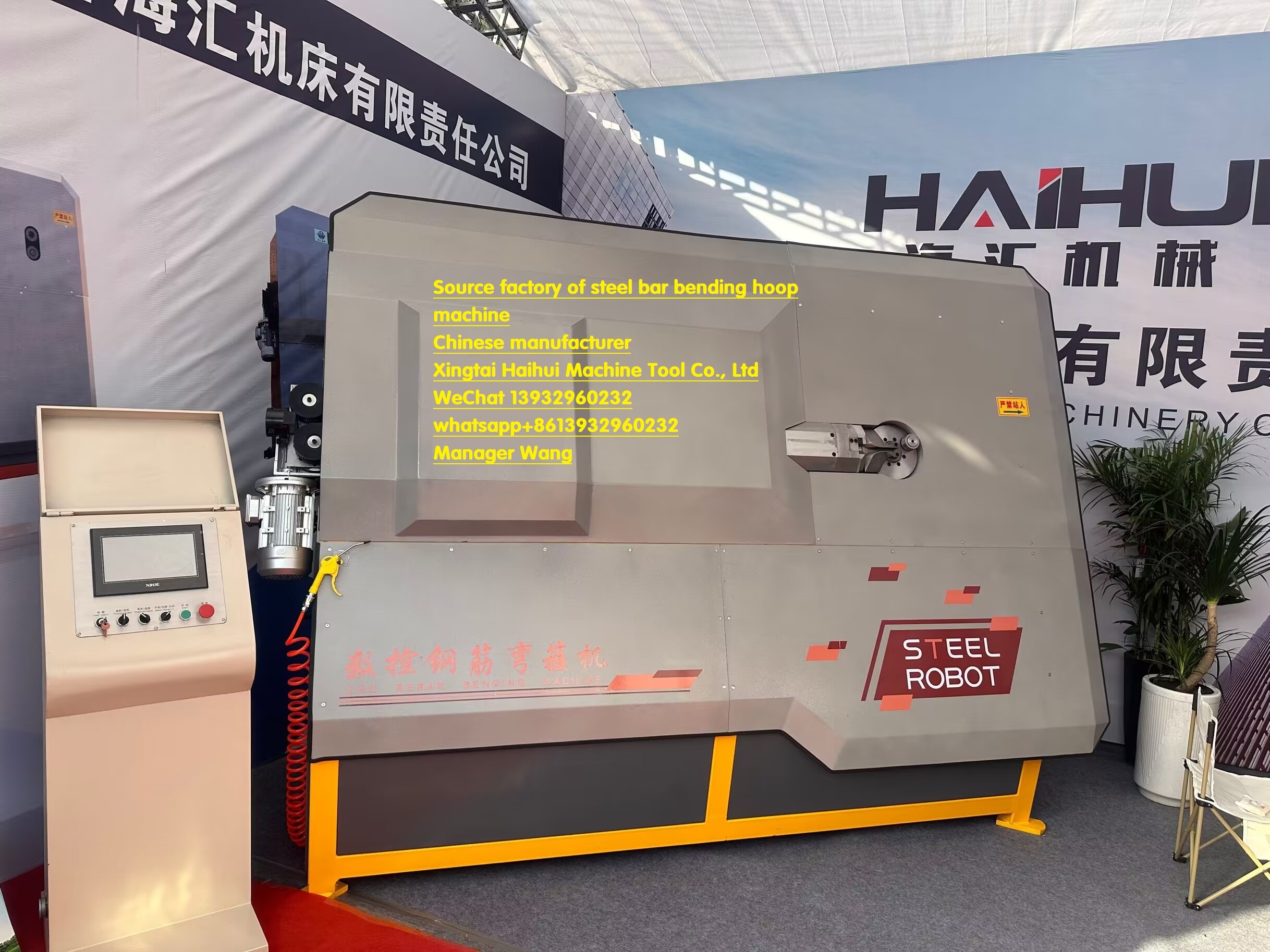

This machine combines cutting-edge computer control systems with precision mechanical engineering to deliver unparalleled performance. It can execute complex bends with astonishing accuracy and consistency, time after time.

The speed at which it operates is a major disruption. It can complete bending tasks in a fraction of the time it would take using conventional methods, significantly boosting productivity and reducing production cycles.

Not only does it excel in speed and accuracy, but it also offers a level of flexibility and customization that was previously unheard of. It can adapt to various materials, thicknesses, and bending specifications, allowing for the creation of a wide range of unique and intricate designs.

The CNC automatic bending machine has also had a profound impact on quality control. By minimizing human error and ensuring consistent results, it has raised the bar for the quality of bent products.

In industries such as aerospace, automotive, and construction, where precision and reliability are paramount, this disruptor has become an indispensable tool. It has enabled manufacturers to meet the ever-increasing demands for complex and high-quality components.

En conclusion, the CNC automatic bending machine has truly disrupted the bending technology landscape. It has not only enhanced efficiency and quality but has also unlocked new possibilities and opened the door to previously unimagined designs and applications.