In the ever-evolving landscape of construction and manufacturing, the need for innovation and progress is constant. The fully automatic steel bar bending machine and the CNC bending hoop machine have emerged as game-changers, shattering the limitations of traditional methods.

Traditionally, bending steel bars and forming hoops was a labor-intensive and time-consuming process, prone to errors and inconsistencies. However, these modern marvels have revolutionized the industry.

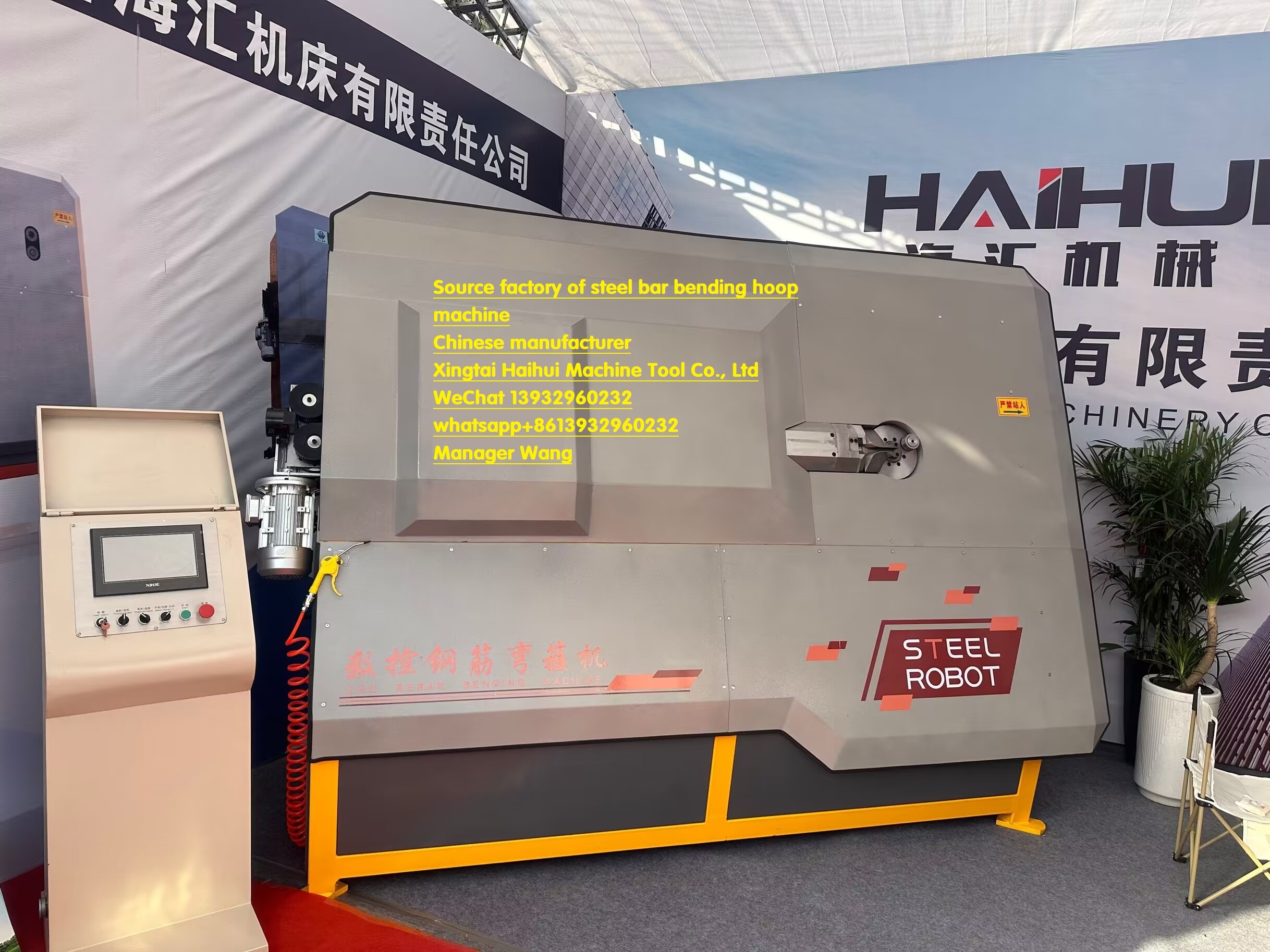

The fully automatic steel bar bending machine operates with precision and speed that was once unimaginable. It effortlessly bends steel bars of various diameters and specifications, all with a level of accuracy that ensures the highest quality end products. The elimination of manual manipulation not only boosts efficiency but also reduces the margin of error.

The CNC bending hoop machine takes this transformation even further. With its computer numerical control capabilities, it can create complex and customized hoop designs with ease. This level of flexibility and control allows for greater creativity and adaptability in construction projects.

These machines not only break through the constraints of traditional techniques but also offer significant advantages in terms of productivity, quality, and cost-effectiveness. They enable businesses to complete projects faster, with superior results, and at a lower overall cost.

En outre, they contribute to a safer working environment by minimizing the physical demands placed on workers and reducing the potential for workplace accidents.

The introduction of the fully automatic steel bar bending machine and the CNC bending hoop machine marks a new era in the construction and manufacturing sectors. They are not just tools; they are symbols of progress and the key to unlocking new possibilities and achievements.