In the realm of construction and metalworking, the pursuit of accuracy and efficiency is paramount. The fully automatic steel bar bending machine and the CNC bending hoop machine have emerged as indispensable tools, delivering exceptional performance in these critical aspects.

The fully automatic steel bar bending machine is a technological marvel that combines precision engineering with intelligent automation. It ensures that each bend of the steel bar is executed with exacting accuracy, meeting the strictest industry standards. The machine’s advanced control systems and calibrated mechanisms guarantee consistent results, eliminating variations and errors that could compromise the structural integrity of the final product.

Simultaneously, it operates at a remarkable pace, significantly reducing production times. Its high-speed processing capabilities allow for a rapid throughput of steel bars, enabling projects to progress smoothly and on schedule.

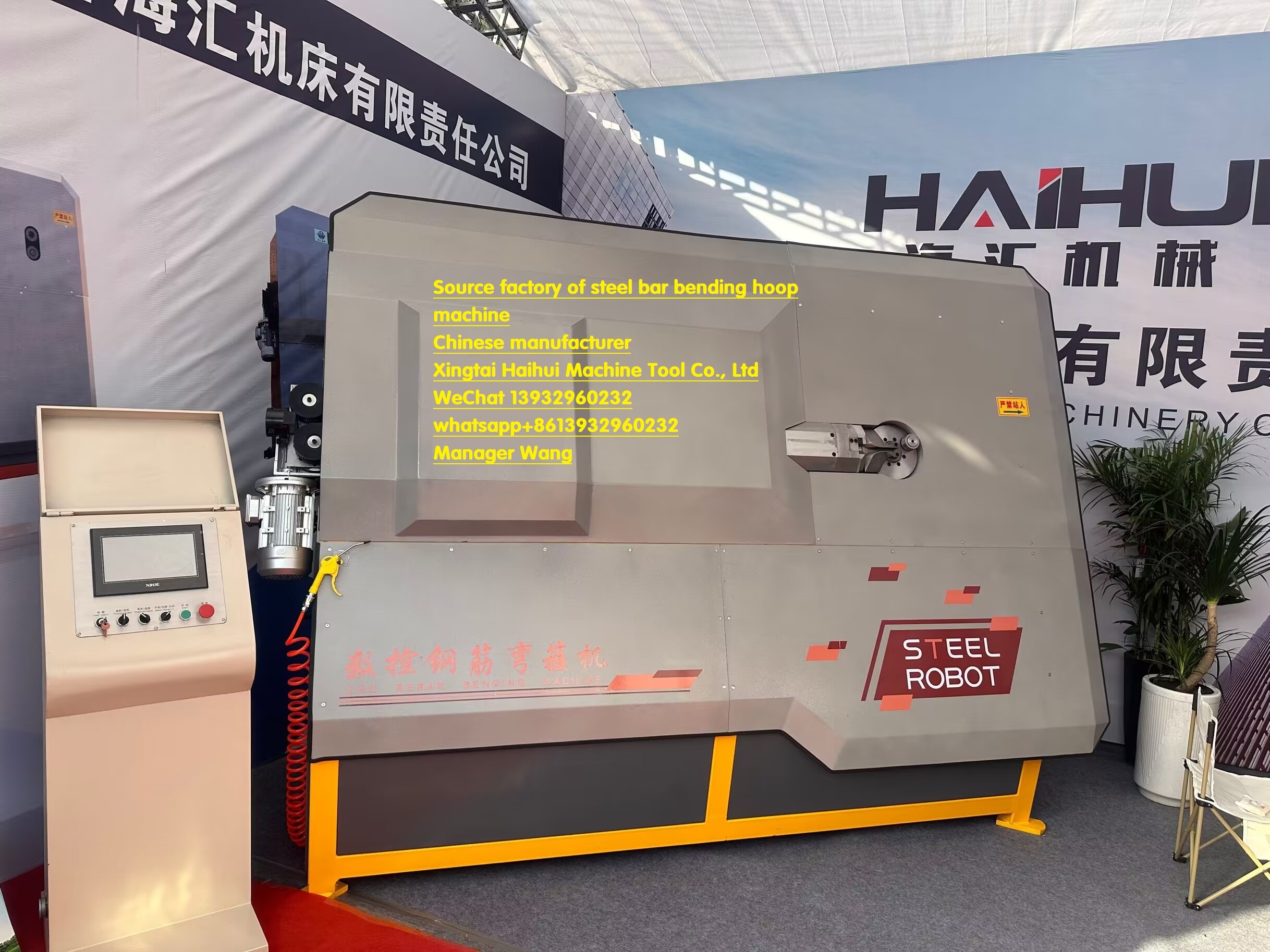

The CNC bending hoop machine is equally impressive in its ability to provide both accuracy and efficiency. With its computer numerical control programming, it can create complex and precisely formed hoops with ease. The machine’s ability to replicate designs precisely time after time ensures that every hoop is of uniform quality and meets the specific requirements of the application.

Not only do these machines offer superior performance individually, but when used in tandem, they form a powerful duo that optimizes the entire steel processing workflow. Their seamless integration and complementary functions result in a highly efficient and accurate production line, minimizing waste and maximizing productivity.

In conclusion, the combination of the fully automatic steel bar bending machine and the CNC bending hoop machine represents the pinnacle of modern steel processing technology. Their ability to deliver accuracy and efficiency makes them essential assets for any operation seeking to excel in the competitive landscape of construction and manufacturing.