Pidevalt areneval ehitus- ja tootmismaastikul, innovation is the driving force behind progress. The fully automatic steel bar bending machine and the CNC bending hoop machine stand at the forefront of this innovation wave, transforming the way steel is processed and shaped.

The fully automatic steel bar bending machine represents a leap forward in efficiency and accuracy. With its advanced sensors and automated controls, it can precisely bend steel bars of various diameters and lengths with minimal human intervention. This not only speeds up the production process but also ensures consistent quality, reducing waste and rework.

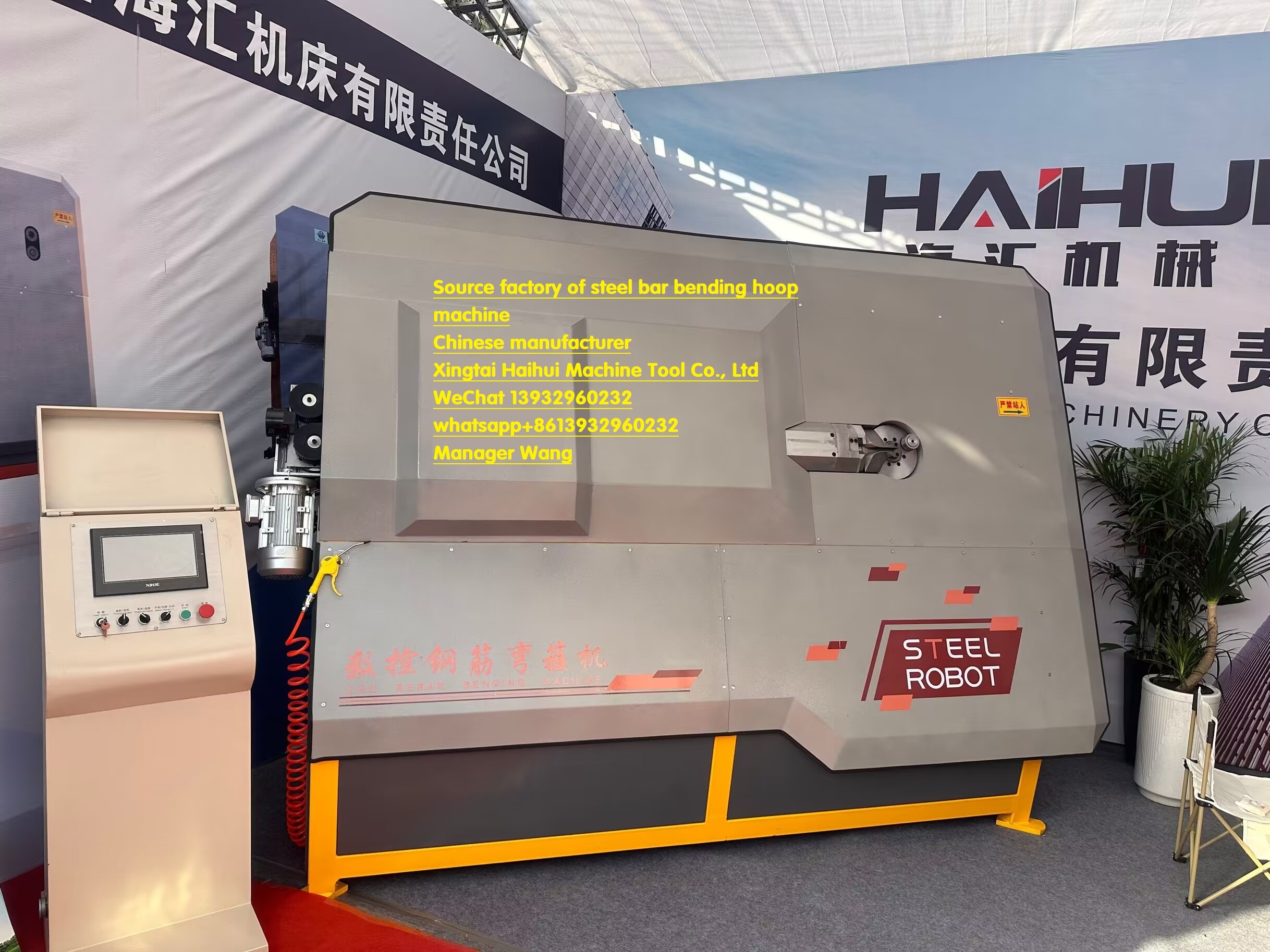

The CNC bending hoop machine takes innovation to the next level with its programmable capabilities. It allows for the creation of complex and custom hoop designs with ease. Operators can input specific parameters and the machine will execute the bending precisely, meeting the exacting demands of modern construction projects that require unique and high-quality components.

These machines are not just about mechanical prowess; they incorporate cutting-edge technologies such as artificial intelligence and data analytics to optimize performance, predict maintenance needs, and even adapt to changing job requirements in real-time.

Innovation in these machines also extends to their design and user interface. They are ergonomically built to ensure operator comfort and safety, while intuitive controls make them accessible to even novice users.

Lisaks, they are part of a larger ecosystem of connected technologies that enable seamless integration with other equipment and systems on the construction site or in the factory, enhancing overall productivity and workflow management.

Kokkuvõtteks, the fully automatic steel bar bending machine and the CNC bending hoop machine are not just tools; they are symbols of innovation that are shaping the future of the industry. Their continuous evolution and improvement promise to bring even more advanced solutions, making construction and manufacturing more efficient, precise, and sustainable.