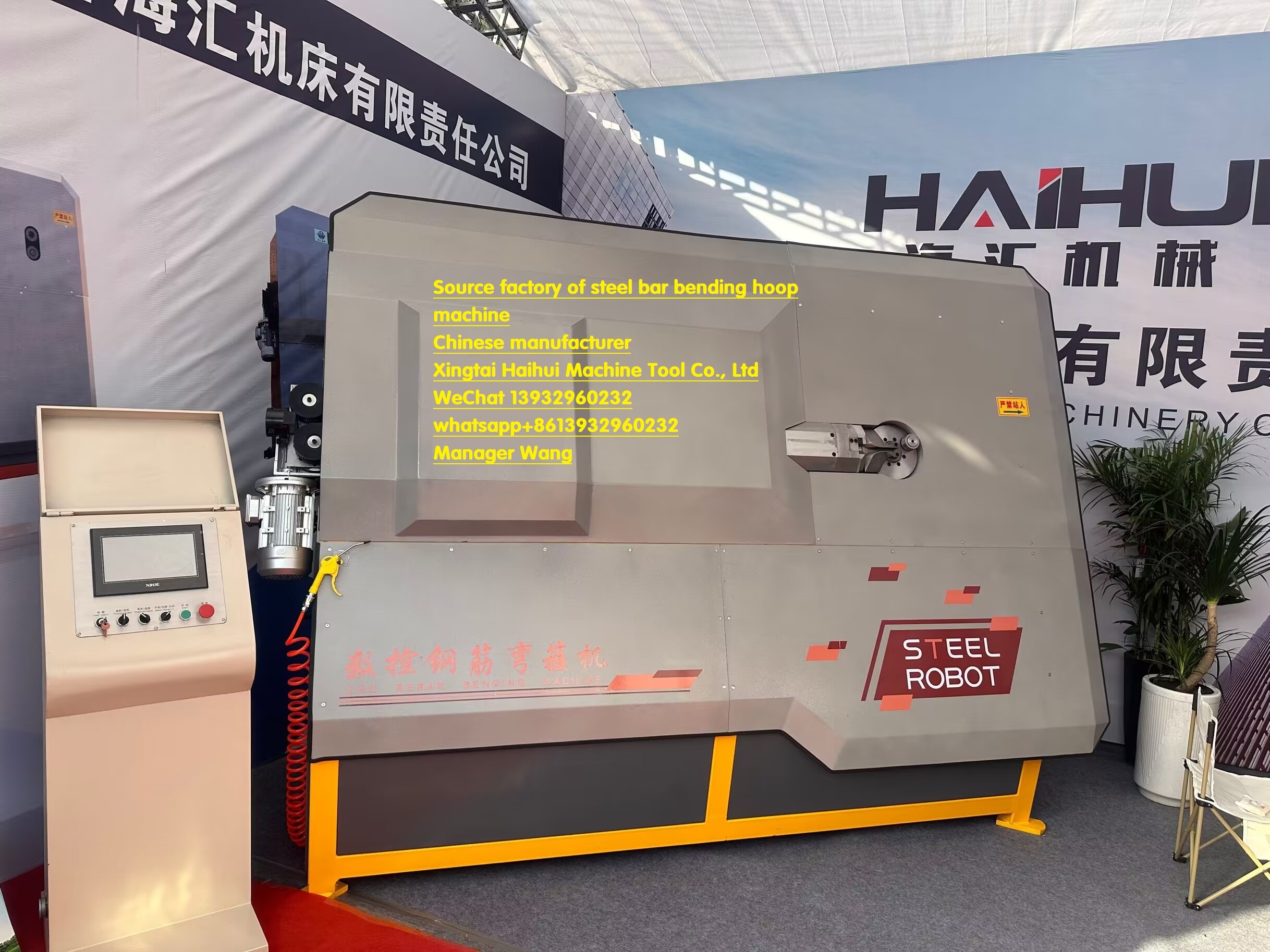

The Fully automatic CNC hoop reinforcement machine has emerged as a revolutionary force, transforming the landscape of hoop reinforcement production and shaping a promising new future.

This advanced machinery represents the convergence of cutting-edge technology and engineering brilliance. Its fully automatic capabilities redefine the efficiency and precision of creating hoop reinforcements.

With its intelligent control systems and precise mechanical components, the machine ensures that each hoop reinforcement is crafted to exact specifications, eliminating variations and ensuring consistency.

The speed and productivity it offers are unprecedented. It can churn out a large number of high-quality hoop reinforcements in a short period, meeting the escalating demands of modern construction projects.

Not only does it enhance the quality of the final product, but it also reduces labor-intensive processes and human errors, leading to significant cost savings and improved project timelines.

The adaptability of the Fully automatic CNC hoop reinforcement machine is another remarkable feature. It can handle diverse materials and complex designs with ease, providing solutions for a wide range of construction needs.

Furthermore, its integration with modern software and digital interfaces allows for seamless communication and monitoring, enabling real-time adjustments and optimization of the production process.

Kokkuvõtteks, the Fully automatic CNC hoop reinforcement machine is not just a piece of equipment; it is a catalyst for change, driving the industry forward and shaping a new era of efficient, high-quality hoop reinforcement production.