In the world of construction and manufacturing, having the right tools is crucial for achieving high-quality results and maximizing productivity. The combination of the fully automatic steel bar bending machine and the CNC hoop bending machine presents an excellent choice that offers numerous benefits and advantages.

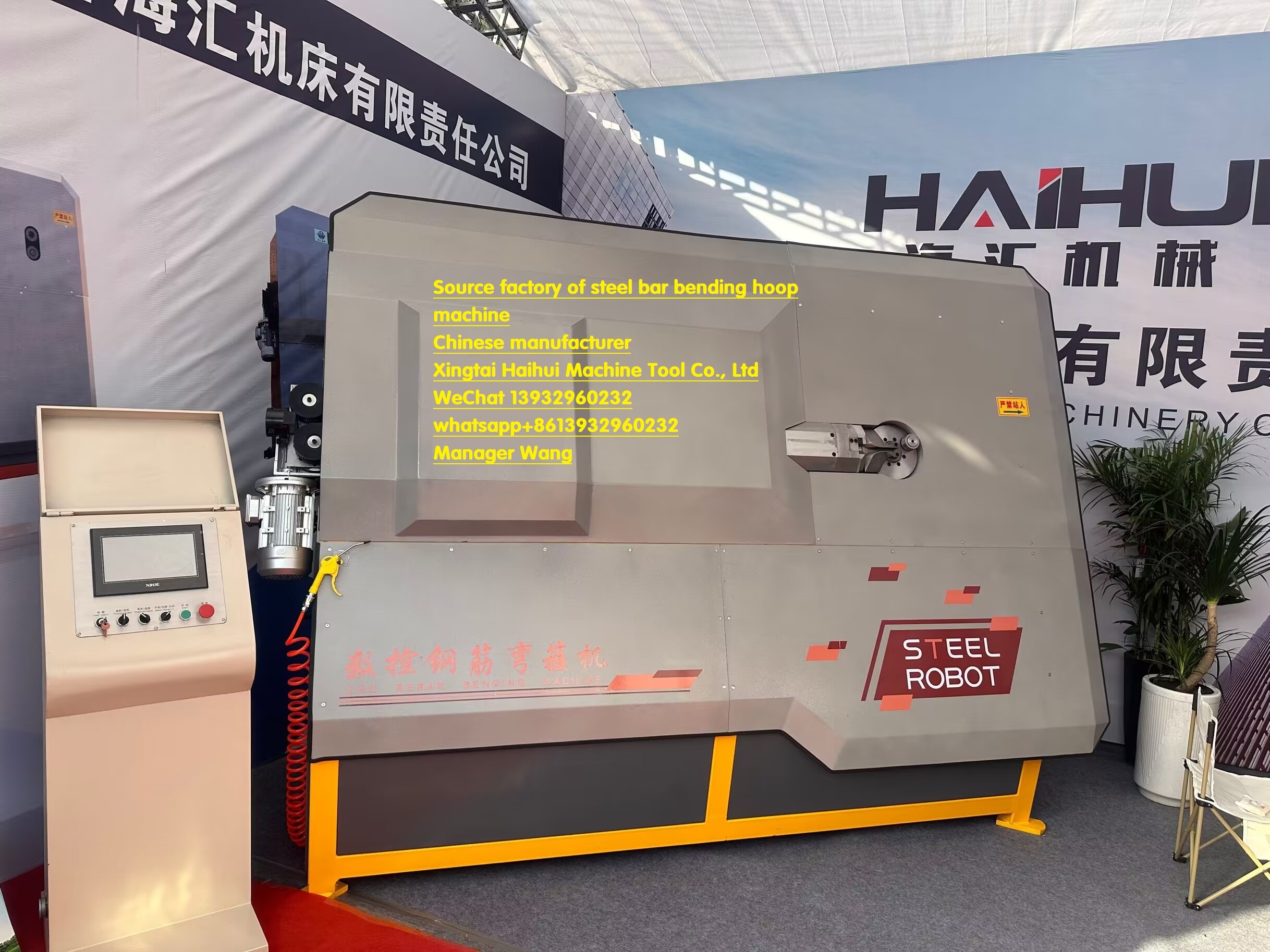

The fully automatic steel bar bending machine is a marvel of modern engineering. It is designed to handle the bending of steel bars with precision and speed. Its automated processes eliminate the need for manual labor, reducing the risk of human error and increasing efficiency. This machine can accurately shape steel bars into various forms and angles, meeting the specific requirements of different projects.

The CNC hoop bending machine, on the other hand, provides unparalleled control and accuracy when it comes to bending hoops. With its computer numerical control technology, it ensures consistent and uniform bends, guaranteeing the quality and durability of the hoops produced.

Together, these two machines form a powerful duo. They streamline the production process, reducing production time and costs. Their ability to produce complex and precise bends with ease makes them indispensable in industries where accuracy and quality are of utmost importance.

Además, these machines are built to last. They are constructed with high-quality materials and components, ensuring long-term reliability and minimal maintenance requirements. This not only saves on repair costs but also ensures uninterrupted operation, maximizing the return on investment.

In addition to their technical capabilities, they also offer user-friendly interfaces and safety features. Operators can easily program and monitor the machines’ operations, while safety mechanisms protect workers from potential hazards.

In conclusion, the fully automatic steel bar bending machine and the CNC hoop bending machine are not just tools; they are strategic assets that provide a competitive edge. Choosing them is indeed an excellent decision for any business or project that demands efficiency, quality, and innovation in steel processing.