In the contemporary construction and manufacturing landscape, the Fully Automatic Reinforcement Bending Machine and the CNC Hooping Machine have emerged as indispensable assets, driven by continuous technological advancements.

The Fully Automatic Reinforcement Bending Machine represents a significant leap in efficiency and precision. Its intelligent control systems and mechanical designs enable seamless handling of reinforcement bars, reducing human intervention and minimizing the potential for errors. The machine’s ability to adapt to various bar diameters and bending specifications showcases its flexibility and versatility.

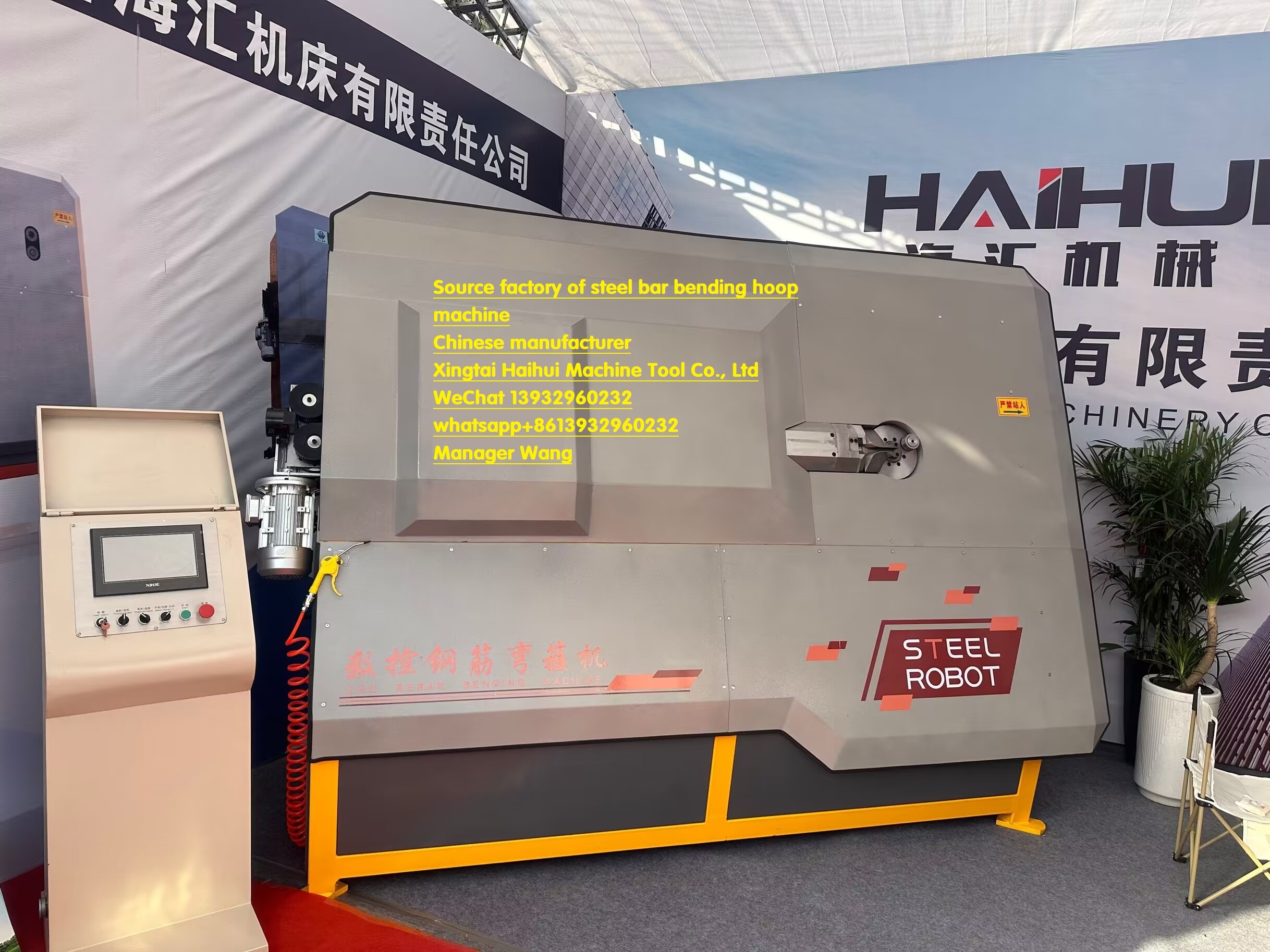

The CNC Hooping Machine, on the other hand, brings a new level of sophistication to the production of hoops. With precise computer numerical control, it can create hoops with intricate designs and exact dimensions, meeting the most demanding architectural and engineering requirements.

From a technical perspective, both machines incorporate advanced sensors and actuators that ensure smooth operation and accurate positioning. The software interfaces are user-friendly, allowing operators to program complex bending and hooping patterns with ease.

In terms of productivity, these machines significantly increase output rates compared to traditional methods. They not only save time but also optimize material usage, reducing waste and costs.

In the context of quality control, the consistent and repeatable performance of the Fully Automatic Reinforcement Bending Machine and the CNC Hooping Machine ensures that each component meets strict quality standards, enhancing the overall reliability and durability of the structures they are used in.

Looking towards the future, ongoing research and development in this field are likely to bring even more advanced features, such as enhanced connectivity for remote monitoring and maintenance, as well as improved energy efficiency.

ختاماً, the Fully Automatic Reinforcement Bending Machine and the CNC Hooping Machine are at the forefront of modern construction and manufacturing technology, offering a combination of advanced capabilities, productivity gains, and quality assurances that are shaping the industry’s future.